Leading-edge Technology,

Stable Quality, Happy to meet various customers needs.

Polymer flocculants

promote floculation by neutralizing the superficial electric charge of sludge

particles in water, and unstabilizing each suspended solid.

The activated

functional group inside the polymer flocculant then causes the particles to

absorb to each other.

The cross-linking

effect of the particles further flocculates the sludge particles and promotes

the formation of still larger flocs.

In the premise of

technology and high performance comparable to international flocculants, our

cost performance advantage is obvious. We are committed to develop various

types of anionic, cationic and non-ionic products for various applications.

Advantages

1.Excellent

floculation

2. Effective at

small dosages

3. Superior clarity of waste water

4. Outstanding filtration and dewatering properties that enhance sludge

dewatering efficiency

5. Product development and production management give primary consideration to

safety

6. In addition to general industrial use including Coal washing, sand washing, the

products are also available to respond to paper-making, dyeing, textile

industry standards wide-ranging needs.

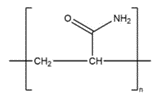

Basic structure

Flocculant

Introduction

Shanghai

Promaterial Industry Co., Ltd develop and provide chemicals Speciality for

water treatment.

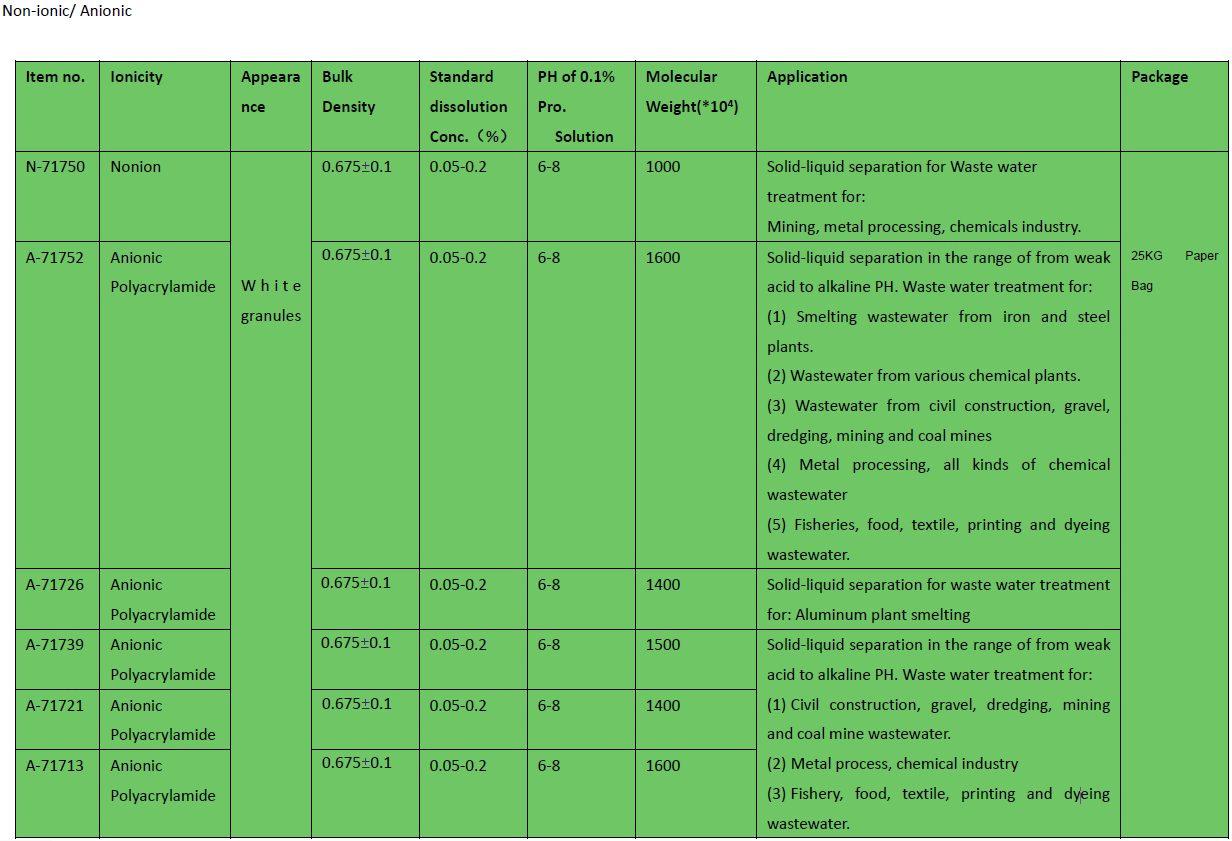

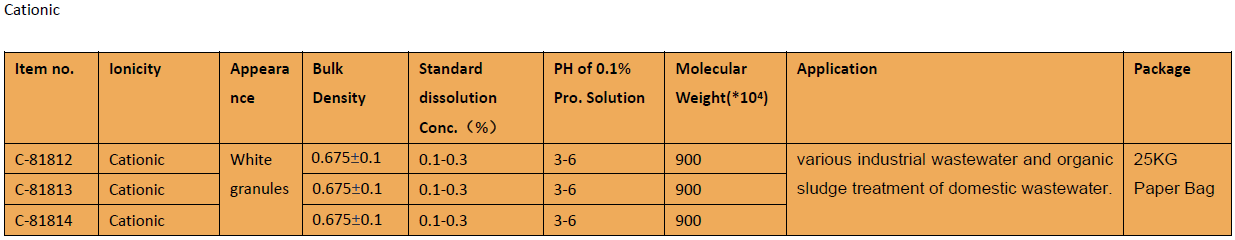

Product Series: Various types of flocculants (anionic, cationic,

non-ionic) are available for the purification of coal, sand, mine wastewater,

general industrial wastewater, textile, printing and dyeing, paper wastewater,

sewage treatment plants, domestic wastewater, etc.

Precautions

1. Usage (safety

goggles and rubber gloves recommended)

When handling large volumes of powder products, powder dust may scatter. When

handling these products, be sure to wear safety goggles, rubber gloves, and a

dust-protective mask.

If the powder product accidentally gets into your eye, do not rub your eye.

Rinse with a steady flow of water for at least 15 minutes, and then consult a

medical specialist.

If the powder product adheres to your face, hands and feet, or any other

exposed skin, wash it away with soap.

If the powder product spills onto the floor or ground, immediately wipe it up

with a cloth or paper. Spilled powder readily absorbs moisture and becomes

extremely slippery, so after wiping, flush the area with a large volume of

water. Scattering sand is also effective as an emergency measure.

For more information, please see the " Material Safety Data Sheet"

supplied with the product concerned.

2. Safe storage

(product life)

Powder type products come in paper bags with inner plastic bags. As they are

all packages designed for indoor storage, please store the product in a well-ventilated

room.

The shelf life of powder products is a one year. It may differ slightly

depending on storage conditions, but please use the product within the

specified period.

The storage stability of dissolved products is extremely low. Although it

differs among anionic, nonionic, and cationic products, please try to use them

as quickly as possible. Note also that performance degradation occurs quicker

particularly in cationic products.

3. Corrosiveness

(products and liquid solutions)

Powder products are non-corrosive toward metals in general. However, the liquid

products are highly corrosive, so avoid contact with steel, aluminum, and other

general metals.

On the other hand, dissolved products are generally corrosive when their

electric conductivity increases. Cationic solutions particularly become

corrosive because they have lower pH levels (they are more acidic).

Based on the above points, recommended materials for equipment that come into

contact with the emulsion/liquid solution, such as the dissolving unit,

dissolver, mixer, piping, and pump, include hard vinyl chloride resin, FRP and

other plastics, and rust-resistant stainless steel.

When using a steel tank, apply an anti-corrosive coat (coal tar epoxy, etc.) to

the inner liner of the tank.

4. Safety

Shanghai Promaterial industry Co., Ltd read through many materials related with

numerous skin tests and animal experiments to verify the safety of

polyacrylamide. Acrylamide (monomer), the raw material used in polyacrylamide

polymer flocculant, has relatively high toxicity. The safety of Acrylamide

(monomer)-based polyacrylamide was confirmed in 1960 following a test of the a

two-year continuous administration experiment on dogs and rats.

Various other experiments have also been conducted showing that polyacrylamide

is pharmaceutically "chemically stable."

However, when handling large volumes of powder type products and when exposing

your skin to them repeatedly or for a prolonged time, be sure to wear safety

goggles, rubber gloves, and other protective gear. Also be sure to wash your

face and hands after use.