| 1) Material briefs: Material Description: Our thermally conductive titanates have been developed to increase their thermal conductivity and heat dissipation properties while retaining their original properties. By adding them to friction materials (automotive, heavy-duty discs, train brake pads and industrial friction blocks), the following effects can be achieved. | |

|

2) Advantages: Excellent thermal conductivity and heat dissipation Large specific surface area Low bulk density Reduced heat recession Prevention of thermal cracking |

|

| Item no.: | RETRAN-PM |

| Applicaltion: | Dedicated to Automotive,heavy-duty discs, train brake pads and industrial friction blocks. |

| 3) Data sheet: | |

| Apparance | Grey powder |

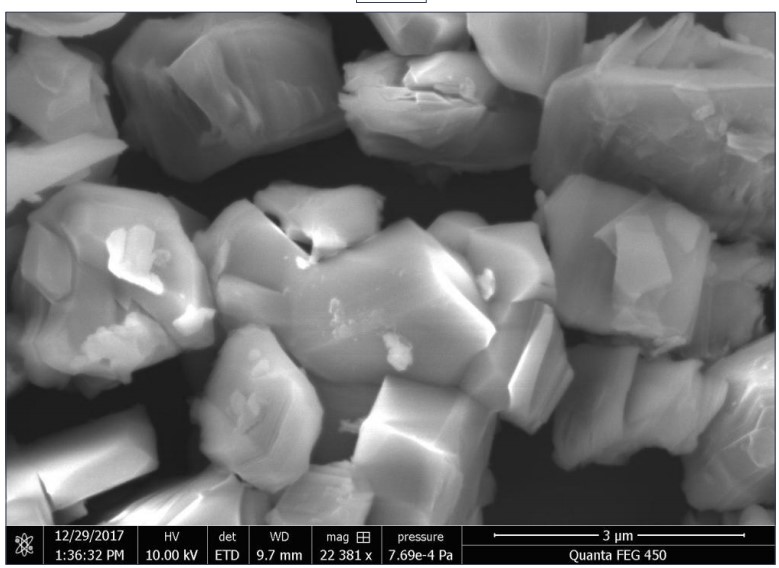

| SEM picture | flaky |

| Chemical composition | Magnesium Potassium Titanium Oxide+layer |

| Average partial size (um, medium size) | 2~10 |

| Bulk Density(g/cm3) | 0.3-0.7 |

| 325 mesh screen pass rate(weight %) | ≥99.5 |

| Specific surface area (m2/g) | 2~5 |

| PH | 10-12 |

| Water(110℃,weight %) | ≤0.7% |

| BET surface area(m2/g) | 20-30 |

| Melting point(℃) | 1350-1400 |

| Friction characteristics | Consistent µ level |

| Package:15kg/bag | |

| Application Features: | |

| Increases the heat dissipation of the brake pad surface, effectively preventing brake pad cracking at high temperatures | |

| Improves high temperature degradability. | |

| Significantly reduces the wear rate of brake discs and pads. | |

| Reduces noise | |