| 1) Material briefs: Titanate salt flacky material has stable friction properties, micro-enhancement, heat resistance and wear resistance. They are used in friction materials, functional coatings for automobiles. | ||

| 2) What we are doing: Thanks to our unique titanate shape and composition control technology, Promaterial has developed new composite materials. Our titanates are primarily used in automotive brake pads as friction modifiers. We continue to expand the range of uses and design new grades with improved properties. | ||

|

3) Advantage: used as a friction modifier to improve μ-stability, wear resistance, fade and NVH. These benefits are based on the physical or mechanical properties caused by the chemical structure and shape of the titanate, and the chemical reactions that occur at the friction interface caused by the chemical nature of the titanate. |

||

| 4)Application field: Dedicated to Automotive brake friction modifier (brake pads, brake linings, clutches, etc.) | ||

| 5) Data Sheet: | ||

| Product name | HJ-TISP-FS | HJ-TISP-FSL |

| Apparance | White powder | White powder |

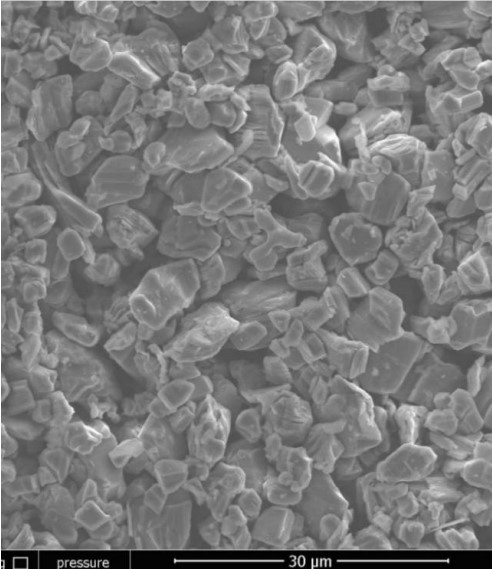

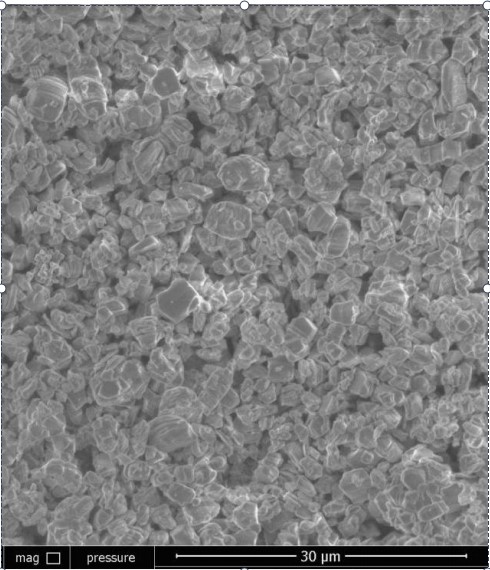

| SEM picture | White flakes | White flakes |

| Structure(XRD) | Potassium Magnesium Titanate | Potassium Magnesium Titanate |

| Stacking Density(g/cm3) | 0.4-0.6 | 0.6-1.0 |

| Average size (um) | 2-6 | 6-10 |

| 325 mesh screen pass rate(weight %) | ≥99.0% | ≥99.0% |

| Specific surface area (m2/g) | 2-5 | 1-3 |

| PH | 10-11.5 | 10-11.5 |

| Water(110℃,weight %) | ≤0.7% | ≤0.7% |

| Melting point(℃) | 1300-1350 | 1300-1350 |

| Mohs Hardness | 4 | 4 |

| Packing: 25kg/kraft bag,total 1000kg/composite pallet, pallet size: 1100X1100X1050mm | ||

|

6) SEM of material HJ-TISP-FS  |